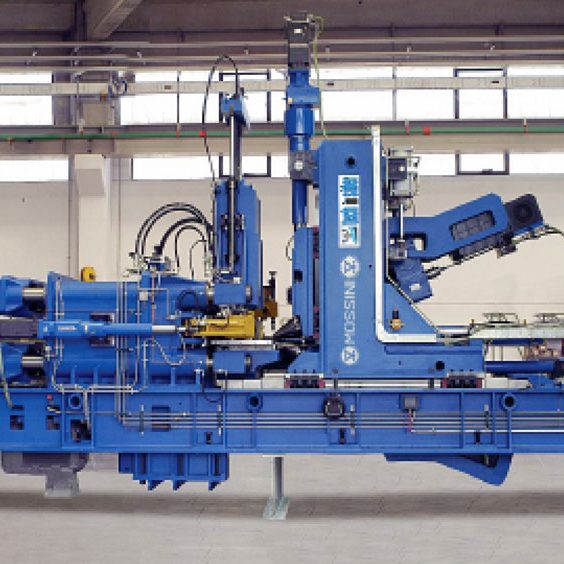

Made for the production of rings by a process of radial – axial hot rolling, the Mossini ring rolling machines of MS series, guarantee a very high quality of the rings and high productivity.

The ring, during the rolling, is put in rotation by the dragging of the radial roller and the axial motorized cones.

The rolling forces are generated hydraulically and are applied to the ring:

- The radial one, by the action of the radial plug-spindle and of the main radial roller.

- The axial one, by the action of the upper axial roller which tends to approach the lower axial roller

A centering device, consisting of two arms actuated by as many hydraulic cylinders, ensures the correct position of the ring during the lamination process.

Automatic operation

The automatic operation ensures, in addition to the reproducibility of the rolling process, a high quality of the rings produced. It occurs through the execution of specific algorithms that, moment by moment, develop and regulate the movements of the tools and the necessary parameters for the rolling of the desired ring.