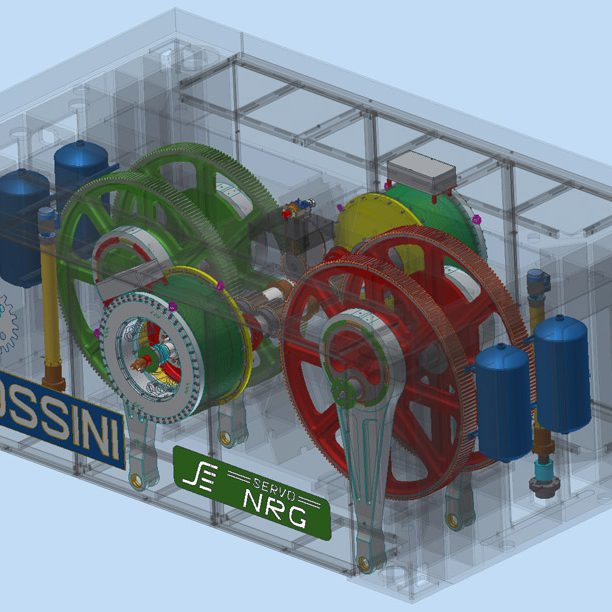

The evolution of species! Missing the flywheel, the clutch-brake unit and the stroke change system. Only a motor and an advanced management system. The Mossini Servo Presses perform all the functions of their mechanical ancestors, and more!

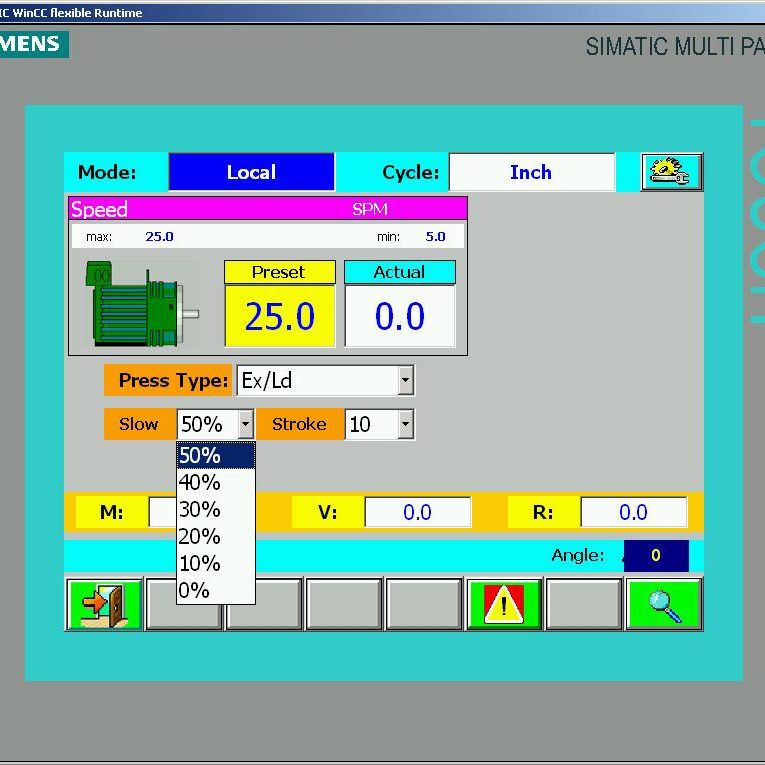

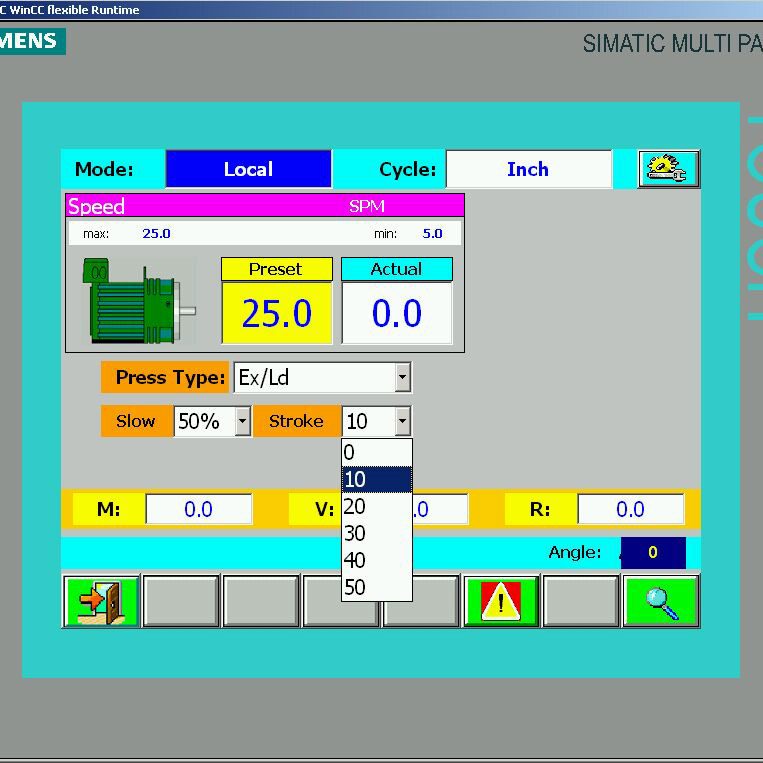

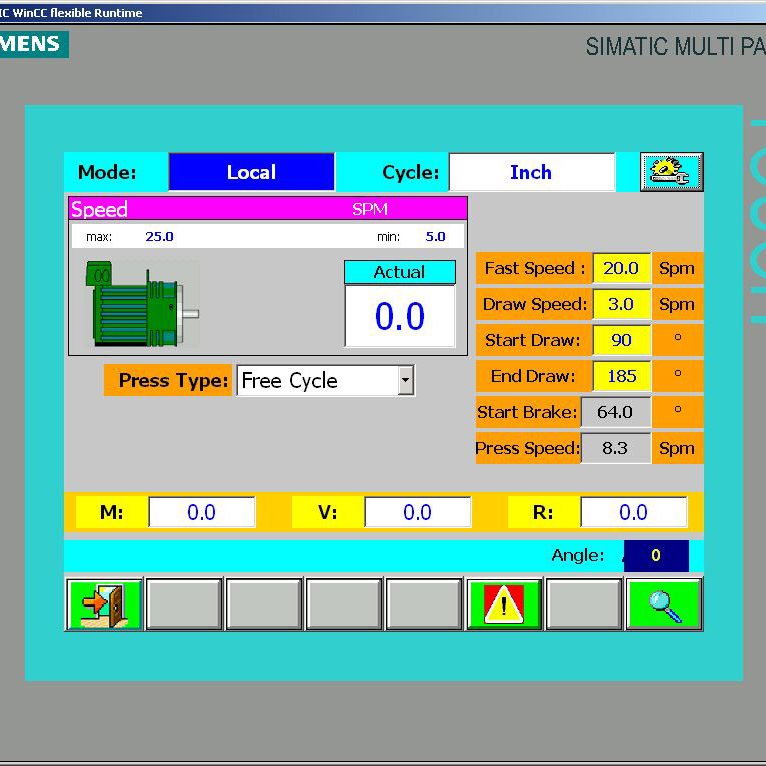

The electric press is a mechanical press, based on the traditional rod – crank kinematic motion, able, however, to adapt to all the requirements of forming, from the coining to the deep drawing. But, it can not only perform all the curves of energy application, typical of all types of mechanical presses, it does even better! All this, thanks to the possibility to adjust speed and position of the slide in real time, and with great precision.

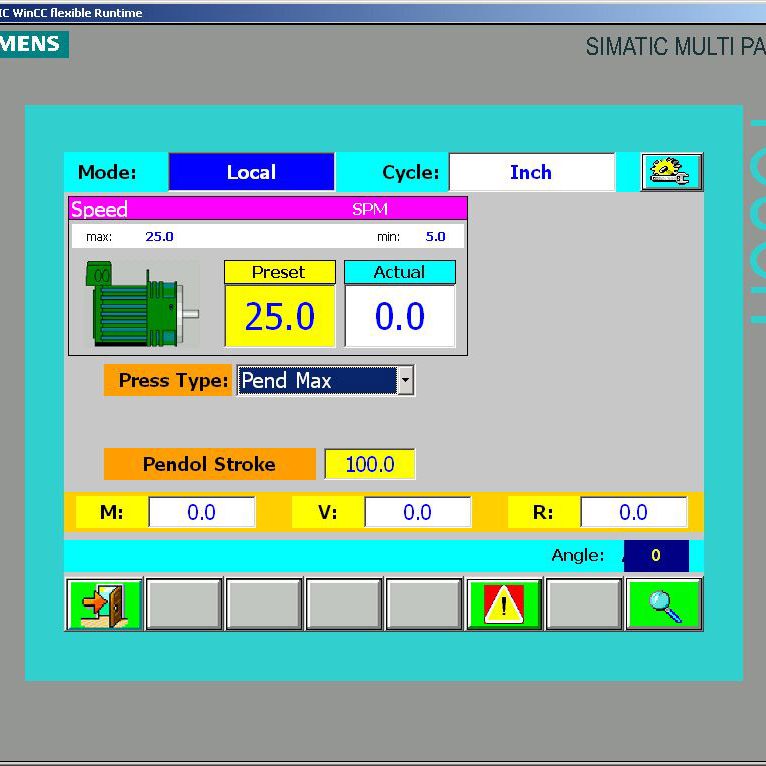

What’s more, from now on, with the new mode Pendulum, having the exact stroke required by your own work is no longer just a dream! Even on machines with 4 connecting rods!

All this has been made possible by two key factors:

- The adoption of a particular type of motor, said Torque, whose main feature is the ability to deliver a high torque value in the constant torque operation area, which, in turn, is particularly wide. Suitably dimensioned, it allows to obtain, even at low speed, values of energy available for forming, higher than those of traditional flywheel machines.

- The implementation of a sophisticated system of monitoring and control, came out from the fusion of a modern and powerful hardware with a software that integrates totally new functions, with the synthesis, and the evolution of the algorithms developed over decades of development and research.

All this, consuming also less energy. The installation of capacitor batteries allows, in fact, the recovery of that one generated by the motor during deceleration phases and its subsequent reuse.

Welcome to the Servo era!