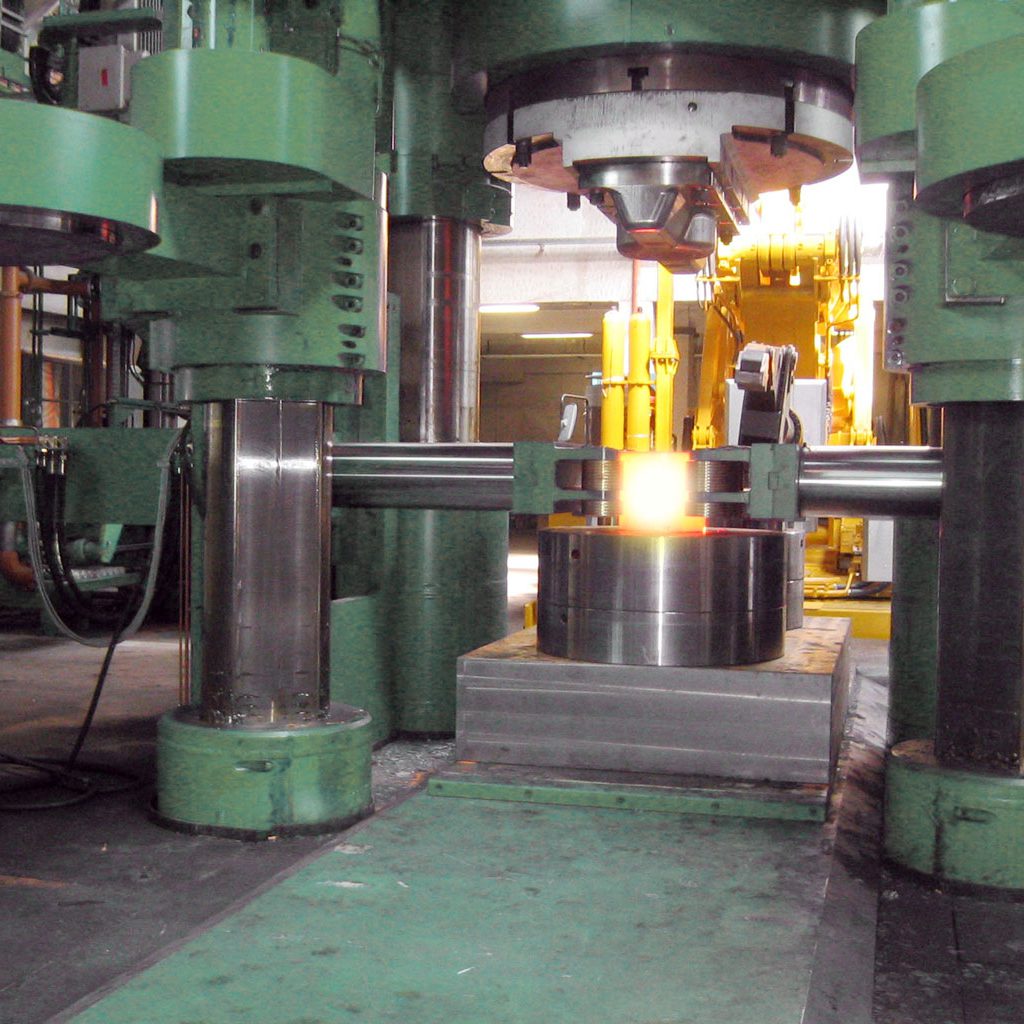

To meet the special needs of this field, Mossini SpA has developed the Hot Forging series. A wide range of hydraulic presses and accessories for every type of work.

They are characterized by:

- Column frame.

- High quality components.

- Electronic regulation of the working parameters: strength, speed and strokes.

- Easy synchronization with any interlocking.

- Programming and store of working cycles from the operator panel.

- Simplified diagnostics from the operator panel.

- Remote assistance.

The series is complete with a full range of accessories designed for various machining requirements.

- Fast hydraulic systems

Dimensioned for high speed forging, with consequent reduction of heat in the oven, and for the finishing. - Upper and lower hydraulic extractors

Available in different types to perform forming, drilling and removal of the bottom. - Tools stores

They enable to arrange the tools out of the press and to automate the exchange of the tools themselves, reducing the time of machine stalking and improving safety conditions. - Moving bolster

Moved by means of hydraulic cylinders located beneath the floor, it is controlled by a joystick placed on the control panel. - Centering and lifting devices

Suitable both for equipment and work-pieces, they allow to run more work operations prepared on the main table. - Systems of rotary tables

Controlled by a joystick placed on the control panel. - Rotating arms of upper tool holder

They contain various equipment. They allow the easy replacement outside press and permit the inclusion in a fast and sequential way.